How To Repair Amd Spindle Assembly

What Is the Spindle Repair Process?

- Share on Twitter

- Share on Facebook

- Follow us on LinkedIn

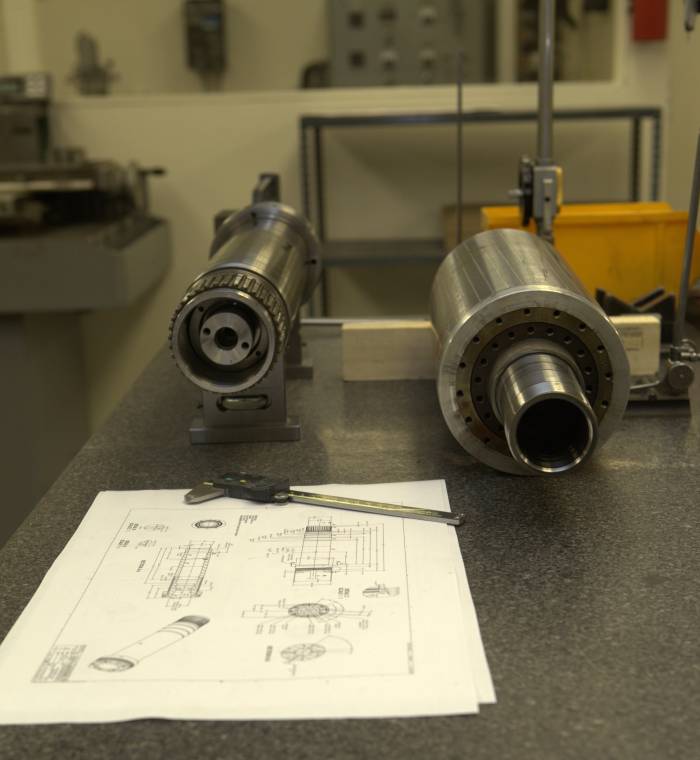

The anatomy and functionality of a spindle is complex. And as such, it takes true expertise to understand, troubleshoot, and repair spindles correctly.

From the moment a spindle repair job hits the loading dock and repair line, a spindle repair company is entrusted with making the necessary adjustments and recommendations to ensure the spindle is returned in working order—and in some cases, in even ameliorate status than before it ever showed sign of original malfunction.

However, though a spindle repair company may see thousands of repairs in whatever given twelvemonth, each spindle repair job is different and must be treated carefully. Depending on the initial diagnosis, a repair may entail multiple processes and applications, such equally dimensional work to a damaged shaft or a grind plate grind of damaged areas. Merely no affair the piece of work, every spindle repair requires 1 or more than spindle repair specialists dedicated to the fix.

Just when you zoom in on such unparalleled precision, what does the spindle repair process really entail?

What to Expect When Working With a Spindle Repair Company

At Northland Tool & Electronics, we execute constructive spindle repairs daily—and we desire you to know how we practice it. So, we've broken down our spindle repair process into these five easy to follow steps:

- Evaluation — This is one of the nigh important steps in the rebuilding process. Upon arrival, every spindle is logged into our production tracking software system. Any bug associated with the incoming status of the spindle every bit related to transit are noted. The spindle is then prioritized and moved to either the disassembly technicians or to the spindle run-up room, depending on the circumstances. This critical showtime step involves our spindle repair technicians working to determine the crusade of failure, which is essential to prescribe the necessary remedies to return your spindle back to action.

- Breakdown — This crucial next step involves spindle repair technicians carefully breaking down the spindle into its component parts while meticulously noting their full general status too every bit specific damage to them. Our technicians likewise photograph the process and perform a full dimensional inspection to identify excessive wear, which may help identify the crusade of failure.

The breakdown process is non complete until the disassembled spindle is given a 2nd look by our production managing director, who reviews and ultimately completes the evaluation mentioned above. The role of the production manager in this process is to farther identify the mode of failure and all other pertinent bug, equally well as come upwards with the recommended cosmetic actions. The production manager will work with the caput of our in-house grinding and machining section to ensure 100% accuracy.

- Quoting Repair Costs — After a thorough evaluation and breakup, our purchasing department sources all replacement part costs and lead times, a quote is generated, given one last final check and is then communicated to the client for blessing. One time we accept received the blessing, product is scheduled and parts are ordered.

- Repair — Before annihilation happens, all of the spindle parts are advisedly cleaned and any grinding or machining operations are completed. Only when all components are available does the spindle continue to our spindle assembly technicians. These highly trained professionals assemble all the spindle components and then perform a rigorous intermission-in procedure, which may include dynamic balancing as well equally thermal and vibration analysis depending on the type of spindle.

- Return— Later a final quality control check is performed, the spindle is given dorsum to our shipping section, carefully boxed to minimize the possibility of in-transit damage, and shipped back to you lot, our customer.

How Long Does a Spindle Repair Take?

The timing of a spindle repair job ultimately depends on the type and size of spindle sent in for repair. It'south as well dependent upon the corporeality of damage and repairs needed. A quick turnaround for an emergency spindle repair job would be 24 hours, only the standard turnaround fourth dimension for a direct repair is between 5-ten business concern days. In some unique cases, depending upon the demand to make repairs or obtain new parts, a spindle repair job can take a few weeks.

And just because we've repaired your spindle and sent it back to yous doesn't hateful you'll no longer hear from usa once again. Along with a newly rebuilt spindle, Northland Tool & Electronics provides our customers with a warranty, as well equally recommendations for additional steps they can take to preclude premature spindle failure in the future. We also offering a Spindle Support Program that features spindle care seminars, vibration analysis, lubrication arrangement inspection, and evaluation, contamination prevention analysis, cause of failure tracking, spindle upgrades, and much more.

Contact us today to get a quote or to learn more our unique spindle repair procedure.

Source: https://www.northlandtool.com/spindle-repair-process-5-step-explanation/

Posted by: bridgesdivichimahme.blogspot.com

0 Response to "How To Repair Amd Spindle Assembly"

Post a Comment